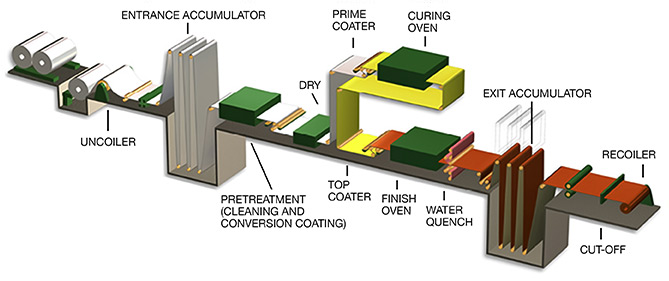

Coil coating is a continuous, automated process for coating metal before fabrication into end products. The steel or aluminum substrate is delivered in coil form from the rolling mills. The metal coil is positioned at the beginning of the coating line, and in one continuous process, the coil is unwound, pre-cleaned, pre-treated, pre-primed, and prepainted before being recoiled on the other end and packaged for shipment. All of this happens at up to 700 feet per minute.

The following steps take place on a modern coating line: